Type - UBM

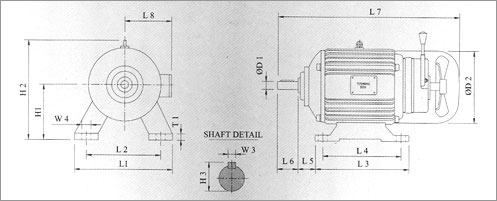

Dimensions - Tefc Foot Mounted Motor With Dc Brake Type UMB

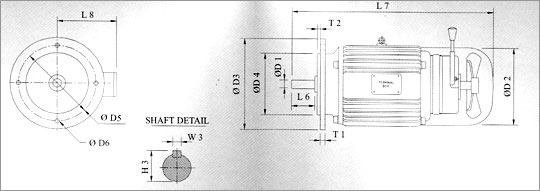

Dimensions - Tefc Flange Mounted Motor With Dc Brake Type UMB

| Parameters | UBM | |||||||||||||||||

| Motor Frame | Brae Size/ Torque Nm |

D1 J6 | D2 | H1 | H2 | H3 | L1 | L2 | L3 | L4 | L5 | L6 | L7 | L8 | T1 | W1 | W3 | W4 |

| 63 | 05 | 11 | 115 | 63 | 158 | 12.5 | 125 | 100 | 106 | 80 | 40 | 23 | 283 | 95 | 10 | 35 | 4 | 7 |

| 71 | 05 | 14 | 140 | 71 | 176 | 16.0 | 140 | 112 | 112 | 90 | 45 | 30 | 313 | 105 | 10 | 35 | 5 | 7 |

| 80 | 10 | 19 | 162 | 80 | 161 | 21.5 | 160 | 125 | 130 | 100 | 50 | 40 | 357 | 128 | 13 | 38 | 6 | 10 |

| 90S | 10 | 24 | 173 | 90 | 177 | 27.0 | 175 | 140 | 132 | 100 | 56 | 50 | 404 | 135 | 14 | 37 | 8 | 10 |

| 90L | 20 | 24 | 173 | 90 | 177 | 27.0 | 175 | 140 | 157 | 125 | 56 | 50 | 429 | 135 | 14 | 37 | 8 | 10 |

| 100L | 35 | 28 | 195 | 100 | 245 | 31.0 | 200 | 160 | 170 | 140 | 63 | 60 | 470 | 165 | 14 | 42 | 8 | 12 |

| 112M | 65 | 28 | 226 | 112 | 285 | 31.0 | 225 | 190 | 175 | 140 | 70 | 60 | 510 | 178 | 14 | 50 | 8 | 12 |

| 132S | 85 | 38 | 260 | 132 | 320 | 41.0 | 258 | 216 | 176 | 140 | 89 | 80 | 568 | 198 | 18 | 55 | 10 | 12 |

| 132M | 155 | 38 | 260 | 132 | 320 | 41.0 | 258 | 216 | 214 | 178 | 89 | 80 | 606 | 198 | 18 | 55 | 10 | 15 |

| 160M | 155 | 42 | 310 | 160 | 390 | 45.0 | 320 | 254 | 260 | 210 | 108 | 110 | 713 | 240 | 25 | 72 | 12 | 15 |

| 160L | 155 | 42 | 310 | 160 | 390 | 45.0 | 320 | 254 | 304 | 254 | 108 | 110 | 773 | 240 | 25 | 72 | 12 | 15 |

| 180M | 250 | 48 | 360 | 180 | 445 | 51.5 | 360 | 279 | 300 | 241 | 121 | 110 | 784 | 260 | 25 | 80 | 14 | 15 |

| 180L | 400 | 48 | 360 | 180 | 445 | 51.5 | 360 | 279 | 338 | 279 | 121 | 110 | 822 | 260 | 25 | 80 | 14 | 15 |

| 200L | 400 | 55 | 390 | 200 | 505 | 59.0 | 400 | 318 | 370 | 315 | 133 | 110 | 903 | 295 | 30 | 85 | 16 | 19 |

- 1Nm=0.102 kgm = 0.737 lb-ft=10.2 kgcm Specifications are subject to change without notice

- All dimensions are in mm only

All dimensions are in mm only.

Solid state AC to DC rectifier will be supplied separately.

Actual appearance of UBM brake motor may not correspond to the figure.

Complete package comprising of motor, brake type USB, UMB or UFB, clutch brake combination alongwith speed reducer can also be offered.

Brake motors with flame proof/crane duty/ textile duty specification can also be offered on request.

| Framewise Braking Torque For Brake Motors | ||

| Frame | Brake Torque (Nm) | |

| Min. | Max. | |

| 63 | 5 | 10 |

| 71 | 5 | 10 |

| 80 | 10 | 20 |

| 90S | 10 | 35 |

| 100L | 20 | 65 |

| 112M | 35 | 85 |

| 132M | 65 | 155 |

| 160M | 95 | 250 |

| 160L | 155 | 250 |

| 180L | 250 | 400 |

| 200L | 400 | 600 |

When to placing an enquiry kindly furnish following details:

● Application details and mounting method

● Output speed

● Duty cycle with number of starts/stops per hour

● Ambient temperature and any other environmental condition

● Braking torque required

● Mounting

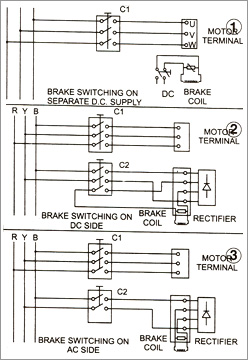

There are three different methods of switching:

● Separate DC supply from control panel to the brake coil, {figure 1)

● AC Switching

In figure 3, brake coil connections are shown at AC side AC switching is recommended when braking time is not critical.

● DC Switching

In figure 2, switching is carried out on DC side. Once braking of the motor takes place intermittently, DC switching must be carried out. A Resistor and Capicitor network must be connected across the brake coil and parallel to it.